Drill bits can get worn out or damaged after a lot of use, especially on tough metals. When this happens, it’s time to change them. But how do you do that? Let’s go over it step by step.

Here at Rotabroach, we make a bunch of different kinds of drill bits and other tools for power drills. Want to learn more? Check out our annular cutters page and our power tools accessories pages.

In this guide, we’ll cover:

How to change a drill bit on a drill without a key (a keyless drill chuck)

How to change a drill bit using a key

What kinds of drill bits we offer at Rotabroach

How To Change a Drill Bit Without a Key:

Step 1: Start by loosening the chuck. That’s the part at the end of the drill that holds the bit in place. Hold the chuck with one hand and the drill handle with your other hand. Twist the chuck counterclockwise to loosen it. You can also just hold onto the chuck and squeeze the drill’s trigger to loosen it.

Step 2: Once the chuck is loose, you can pull out the old drill bit. If it looks old or damaged, make sure to get rid of it so you don’t accidentally use it again.

Step 3: Hold the new bit with your thumb and pointer finger so that the flat part (that’s the shank) is facing the chuck. Push the bit into the chuck and pull it back towards you. Keep holding onto the bit and the chuck since the bit isn’t secure yet.

Step 4: To secure the bit, squeeze the drill’s trigger a few times while still holding onto the bit. This will make sure it’s straight.

Step 5: If your drill has a ratcheting mechanism for extra pressure, twist it clockwise next to the chuck to lock it in. You’re all done.

How To Change a Drill Bit Using a Key:

Step 1: If your drill came with a key, you’ll need it to loosen the chuck. Match the key’s teeth with the teeth on the chuck and put the tip of the key into one of the holes on the side of the chuck.

Step 2: Turn the key counterclockwise to open the chuck. Keep turning until the chuck is open enough for you to take the drill bit out.

Step 3: When the chuck is loose enough, take the bit out with your thumb and pointer finger. Be careful not to let the bit fall out if the drill is turned upside down. Once you’ve taken out the bit, check if it’s damaged. If it is, throw it away so you don’t use it by mistake later on.

Step 4: With the chuck fully open, put the new bit into the drill. Hold onto the bit and the chuck so they don’t fall out.

Step 5: While holding the bit with one hand, use the other hand to turn the key clockwise. This will tighten the chuck. Once the bit is secure, you can remove the key.

When changing a drill bit, keyed or keyless, it’s essential to consider safety. Here’s some quick safety tips to avoid risk when changing drill bits:

Switching out a drill bit might seem like a simple task, but safety should always be your first concern. Here are a few key safety considerations to keep in mind:

Power Off: Before you start, ensure the power tool is turned off and unplugged from the power source. Never attempt to change a drill bit when the tool is still connected to power.

Use Correct Equipment: Always use the correct equipment when changing a drill bit. If your drill requires a key, ensure you use the appropriate one.

Wear Safety Gear: Protect yourself by wearing the appropriate safety gear. This may include safety goggles to protect your eyes from any flying debris and gloves to protect your hands.

Avoid Loose Clothing: Loose clothing or dangling jewelry can get caught in the drill during the process, leading to accidents. Therefore, ensure you’re wearing tight-fitting clothing and have removed any potential hazards.

Inspect the Bit: Before installing the new bit, inspect it for any damages. A broken or damaged bit can break during operation and potentially cause injury.

Remember, changing drill bits doesn’t have to be difficult. With these steps, you’ll be able to do it easily and safely.

The Rotabroach Range:

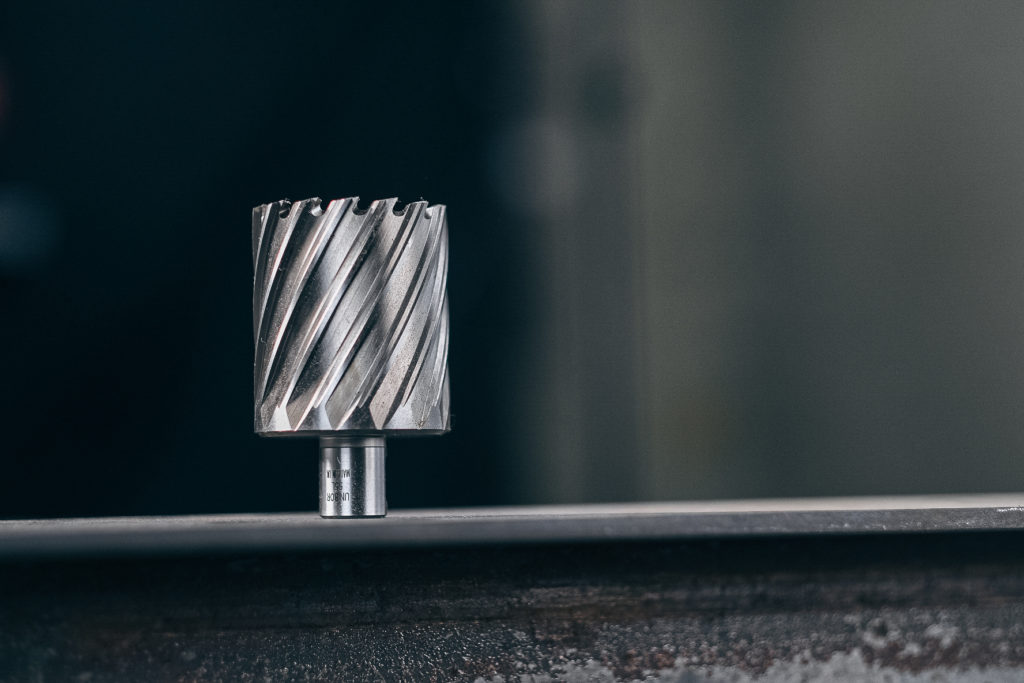

At Rotabroach, we manufacture a range of different drill bits and cutters from our Sheffield headquarters.

As #theoriginalname in metal cutting tools, we’re proud to produce our market-leading range internally, exported to over 70 different countries worldwide. Our range includes:

M2AL Annular Cutters

Manufactured from heat-treated steel with specialist Rotabroach geometry, our M2AL annular cutters are the optimal solution for cutting through lower-tensile steels (>900N) quickly and easily. Budget-friendly, effective and long-lasting, our M2AL range is a site essential across the world.

TCT Annular Cutters

Designed with additional Tungsten Carbide Tips (TCT), our TCT annular cutters are ideal for cutting through higher-tensile steels, alloys and other tough surfaces, without compromising on tool life.

Rail Cutters

Our annular cutter range also includes specialist Rail drilling options, uniquely designed to perform on tough rail track. With both M2AL and TCT options available, as well as our rail drill range, we’ve got everything necessary to take on the world’s toughest rail drilling applications.

TCT Holesaws

Designed to make quick, clean cuts in tough metals with a handheld power drill, our TCT holesaw range cuts 10x faster, whilst lasting 3x longer, than comparable bi-metal holesaws. Ideal for HVAC, plumbing and electrical work, they also feature spring-loading for easy waste ejection.