Chop Saws vs Mitre Saws: A Comprehensive Guide

Mitre Saws and Chop Saws are some of the most commonly-found sawing options in workshops and sites around the world. However, despite their shared popularity, they’re used for very different purposes. In this article, we’ll take a look at some of the key differences between the two.

Chop Saw: An Overview

A chop saw, also known as a cut-off saw, is a heavy-duty power tool primarily used for straight, precise cuts in a variety of materials, particularly metal and other tough surfaces. It is characterized by its robust construction, larger blade size (typically around 14 inches), and high power, making it a preferred choice for industrial and construction settings where durability and raw cutting power are essential.

A chop saw operates by lowering a spinning blade onto a material placed on a fixed base, using a pivoting arm. This design allows the operator to cut materials quickly and with high precision, but the cuts are limited to 90-degree angles.

Safety features on chop saws usually include a blade guard to protect against flying debris and a vice or clamp to securely hold the material being cut.

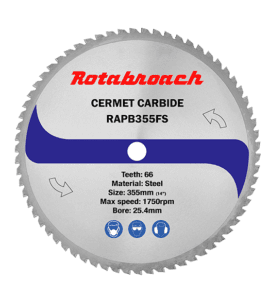

Our market-leading chop saw, the Rotabroach Element 14, is designed to produce quick, clean and cool cuts in a variety of different metals. Capable of producing burr-free cuts in metal without excessive sparks, our Element 14 and range of Rotabroach saw blades don’t generate significant heat during cutting, meaning the workpiece stays cool even immediately afterwards.

A Chop saw is therefore ideal for taking on tough metals and cutting large quantities, whilst it is limited to 90° cuts this doesn’t diminish it’s value to fabrication shops and construction sites worldwide.

Mitre Saws: An Overview

A mitre saw, on the other hand, is a more versatile power tool designed to make accurate cuts at a variety of angles. It comes equipped with a blade typically ranging from 8 to 12 inches in size and a table that can pivot left and right for mitre cuts. Some mitre saws also feature a tilting head for bevel cuts or a combination of mitre and bevel cuts, known as compound cuts.

Mitre saws are popular in woodworking for trim work, framing, and molding, where angled cuts are necessary. They are also favoured for DIY projects and home renovations due to their precision and flexibility in making different types of cuts.

Similar to chop saws, mitre saws also come with safety features such as blade guards, but they usually do not feature a vice or clamp as the material is generally held against a fence during cutting.

Mitre saws are therefore not suited to heavy-duty metalworking like the chop saw, instead they are designed for woodworking and more intricate cuts.

Key Differences Between Chop Saws and Mitre Saws

Making Your Choice: Chop Saw vs. Mitre Saw

Selecting the right power tool depends on your specific needs and project requirements. If your job involves making a high volume of straight cuts in heavy-duty materials, then a chop saw’s power and durability will serve you well. Conversely, if your project requires a variety of precise, angled cuts – for instance, in cabinetry, framing, or other intricate woodworking tasks – a mitre saw will likely be your tool of choice.

However, it’s important to remember that while these power tools can offer exceptional performance, they also demand a certain level of skill and safety awareness. Always ensure you have the necessary training to operate these tools safely, wear appropriate safety gear, and follow the manufacturer’s operating instructions to mitigate any potential risks.

Both chop saws and mitre saws play vital roles in construction, woodworking, and DIY projects. Each tool offers unique advantages and capabilities – the chop saw’s strength lies in its power and durability for making straight cuts and work with tough metals, while the mitre saw offers versatility and precision for a range of angled cuts. Understanding these differences can help you choose the right tool for your specific tasks and ensure that your projects are completed efficiently, accurately, and safely.