With heritage ranging all the way from cutlery-making references in Chaucer’s ‘Canterbury Tales’ through to 1997’s ‘The Full Monty’ and beyond, Sheffield’s reputation for manufacturing has been the enduring identity of the Steel City, even as the world changes beyond recognition.

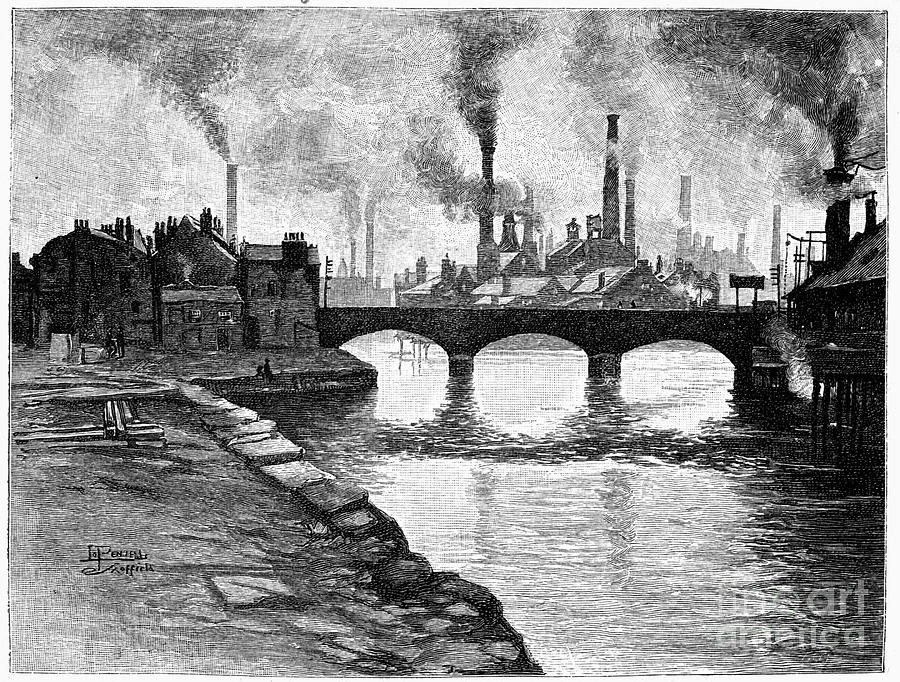

From the beginning, Sheffield’s unique geography provided excellent steel-making conditions; its hills providing coal, iron and other raw materials, the seven rivers with waterpower and the forests, wood and charcoal.

Long before the large-scale industrial operations we know today, self-employed craftsmen (known as ‘little mesters’) produced cutlery, tools and other goods independently. However, as the eighteenth century went on, growing demand began to require more complex operations, with these craftsmen renting workshops in factories, eventually specialising in different production stages, such as grinding, forging and finishing.

In 1742, manufacturer Benjamin Huntsman’s ‘crucible steel process’ revolutionised steel production, creating tough high-quality steel in larger batches than before. This moved Sheffield from a township into a leading European industrial city, with the following century seeing its annual steel production explode from 200 tonnes to 80,000 tonnes, nearly half of Europe’s total production.

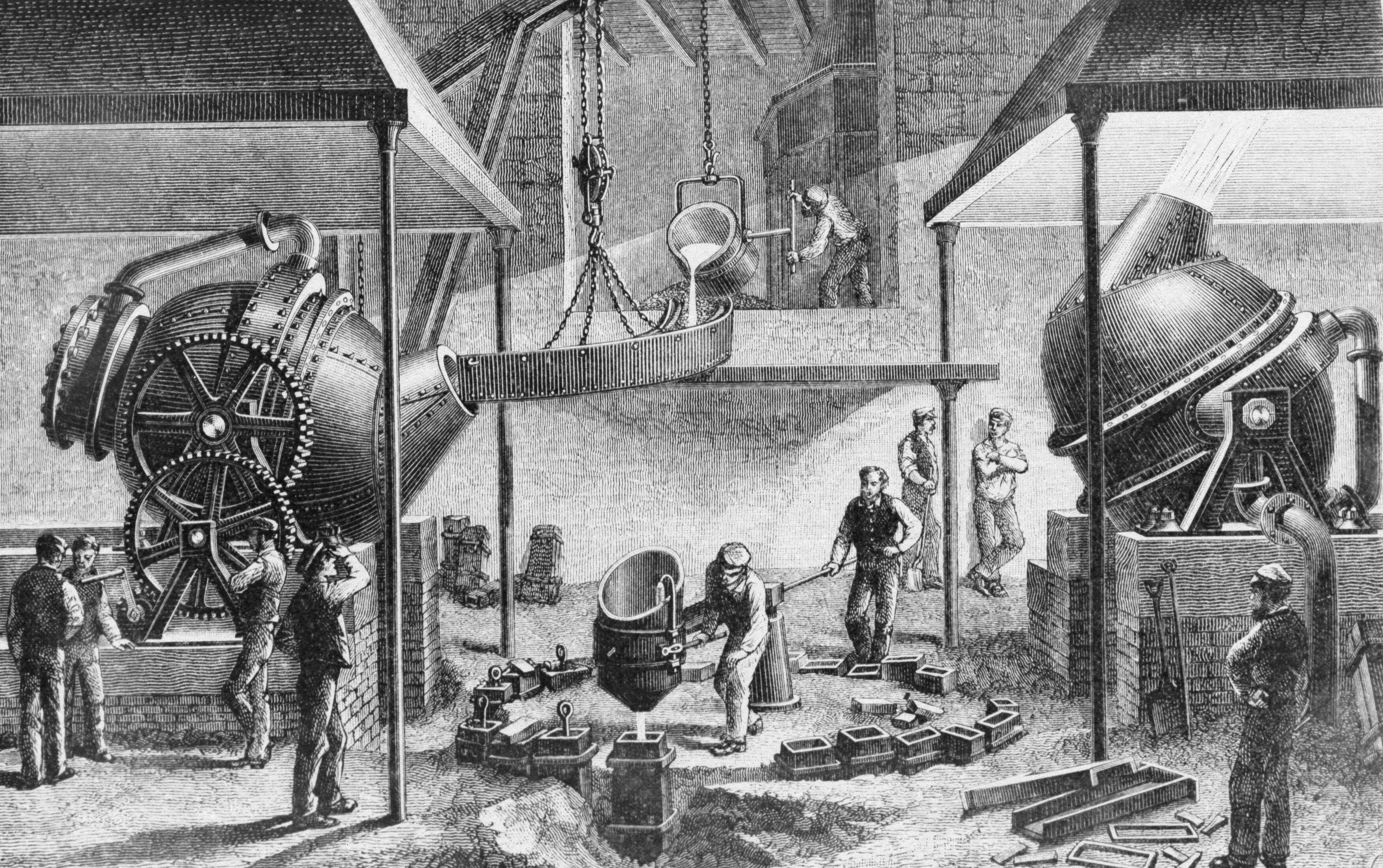

Just over a century later, Henry Bessemer’s converter furnace would take things even further, enabling cheap refined steel to be mass produced and used for railway parts and construction.

John Brown, the first Sheffield steelmaker to be knighted, took the first Bessemer steel license in 1860, developing a rolling technique for armour plate in the same year which lead to him supplying material for almost all of the British Navy’s armour-plated vessels.

This ‘Bessemer Boom’ sent Sheffield steel global, with America importing over three times as much railway track from Sheffield as it produced domestically by 1871.

Fast-forward to 1912, Sheffield-based chemist Harry Brearley invented stainless steel, whilst 12 years later Dr W. H. Hatfield, from the same laboratory, created ‘18/8’, a common form of stainless steel which is 18% chromium and 8% nickel, making it resistant to corrosion and oxidization.

During both World Wars, Sheffield was integral in arming the military. With the men of the city away fighting, the women took over the steelworks, including critical munition production lines. This was commemorated by the ‘Women of Steel’ statue in Sheffield’s centre, unveiled in 2016.

However, in more recent years Sheffield’s steel industry has shrunk significantly. Market downturns, economic turbulence and government/union conflicts all combined to Sheffield losing over 50,000 steel and engineering jobs in 1980-83. The following years saw fresh difficulty from these economic factors, with the industry seeing a number of high-profile plant closures.

These days, Sheffield’s steel industry employs around 2,600 people (as of 2016) and focuses on specialist trade, with many craftsmen working in smaller workshops and producing bespoke goods.

Moving forwards, this heritage is maintained across the city by manufacturers, fabricators and craftsmen of all backgrounds, united by a common sense of quality and prestige that has bound the city together for centuries.

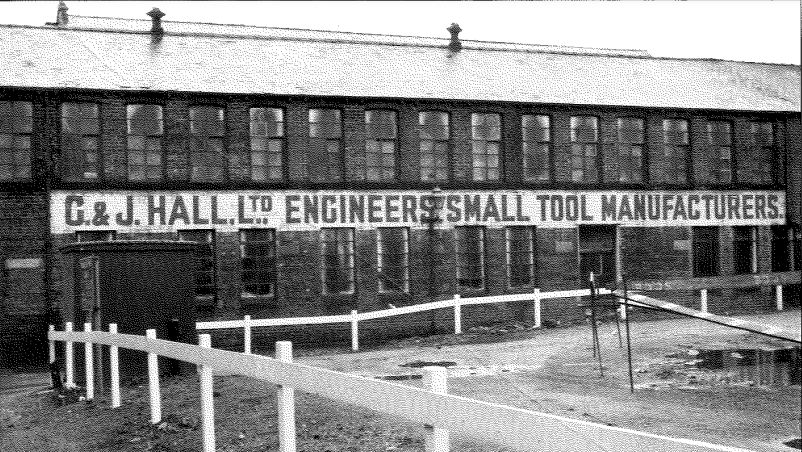

As a Sheffield-based business, we’re proud to embody the global reputation the city has for high standards and a strong manufacturing pedigree, with our commitment to producing top-class products remaining at the centre of everything we do. Our history has been intertwined with Sheffield for centuries, with G&J Hall beginning operations at Hereford Street, before eventually moving to Burgess Road, the site of today’s OSL Group headquarters. George and Joseph Hall were crucial manufacturers of taps (used to form threaded holes for screw fittings) and other tools, with George receiving the prestigious title of Master Cutler in 1904.

G&J Hall’s heritage is just one part of the rich history that runs through our organisation, binding us to Sheffield through a collective pride in the city’s manufacturing prowess. Moving forwards, we continue to embody this same spirit of innovation that guided our predecessors, investing in cutting-edge manufacturing techniques and technologies to provide new, high-quality cutting tools to a growing number of worldwide clients.

Sheffield remains an important city, both historically and in our contemporary world, with its culture, research and people having an impact far beyond the city’s limits. At Rotabroach, we’re proud to be a part of this heritage, and we strive to add to it every day.